Page 193 - 2024 Hopkins Aftermarket Catalog

P. 193

The Lumax Advantage

®

Lumax® Grease Fittings are Precision Engineered to

ensure that they are Stronger and more Durable for

Heavy-Duty Service and Trouble-Free Performance.

Lumax® Grease Fittings are Manufactured from

the Highest-Grade Materials and to Rigid Quality

Standards.

All Lumax® Grease Fittings meet the Specifications as

per SAE J-534 and other International Standards. Each

Grease Fitting goes through several Quality Control

Checks to assure the Highest Quality Level:

• Fully Hardened for extra Durability and to protect

them from Wear due to Constant Use

• Ball Check in the Head Prevents Dirt and Grit from

getting into the Fitting

• Heavier Wall Thickness for Extra Strength

• Zinc Plated with Yellow Passivated Finish, for

Maximum Protection against Corrosion

• Stress Relieved and Tempered Carbon Steel Spring

• Every Fitting is Individually Inspected and Batch

Tested to 5,000 PSI (344 Bar)

• Designed to meet the Demanding Requirements

of most Truck, Automotive, Agricultural, Industrial,

Marine, and Construction Equipment needs

• Apart from Standard Types, Lumax® ® offers an

Extensive Line of Specialty Fittings in a Variety of

Extensive Line of Specialty Fittings in a Variety of

Ext ensiv e Line of Specialty Fittings in a V ariety of

tic and Int

Grades with Domestic and International Standard

tional S

erna

Gr

d

tandar

Grades with Domestic and International Standard

ades with Domes

threads, in Custom Design Versions

• Lumax® offers all Grease Fittings in Bulk and in a

Lumax® offers all Grease Fittings in Bulk and in a

Variety of Attractive Retail Packaging

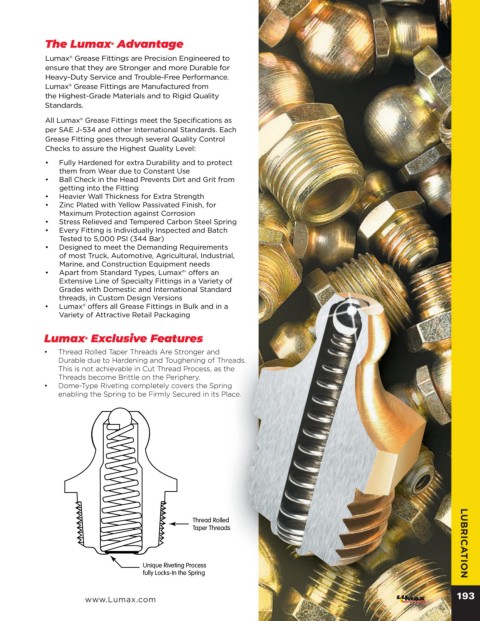

Lumax Exclusive Features

®

• Thread Rolled Taper Threads Are Stronger and

due

T

and

Har

dening

o

able

hr

T

eads.

Dur able due t t o Har dening and T oughening of T hr eads.

Dur

oughening

of

Durable due to Hardening and Toughening of Threads.

T his is not achie v able in Cut T hr ead Pr oc es s, as the

This is not achievable in Cut Thread Process, as the

This is not achievable in Cut Thread Process, as the

Threads become Brittle on the Periphery.

Dome-Type Riveting completely covers the Spring

• Dome- T ype Riv eting c omplet ely c o v ers the Spring

Dome-Type Riveting completely covers the Spring

enabling the Spring t o be Firmly Secur ed in its Plac e .

enabling the Spring to be Firmly Secured in its Place.

enabling the Spring to be Firmly Secured in its Place.

Thread Rolled

Thread Rolled

aper Threads

T Taper Threads LUBRICATION

Unique Riveting Process

fully Locks-In the Spring

www.Lumax.com 193